2021

The year climate change got real.

Flooded subways became a thing. “Extreme weather” became “weather.” Record rains washed away an entire town in Germany, while cars bobbed in streets-turned-to-rivers in Italy, France, Spain, England, and New England. It rained on Greenland’s summit for the first time on record.

Where it wasn’t raining, it was burning from the American West to Siberia. Europe baked while Greece went up in flames. And Texas, the poster-child of everything extreme in the 21st century, froze, fried, and washed out.

Megadroughts. Megafires. Heatwaves. Flash floods. The Polar Vortex. Torqued up hurricanes. Hail storms. Lots and lots of hail storms. (Even the Dolce & Gabbana show in Venice was pummeled.)

But climate change (or climate weirding, as some call it) isn’t the only legacy of fossil fuels. While CO2 and other greenhouse gases (GHGs) accumulated, molecule by molecule, far above our heads, wrapping the planet in a gossamer, heat-trapping cloak, plastic by the ton filled every nook and cranny down below. A plastic bag was even spotted in the Mariana Trench, the deepest place on Earth.

Plastic is actually a triple threat:

-

Its manufacture emits GHGs. Global warming

-

It takes centuries to decompose in landfills, and piles up everywhere else, including oceans. Lots of garbage

-

It releases a devil’s brew of toxic chemicals when it breaks down. Pollution

According to a new report, Plastic & Climate Change, “Plastic is the new coal.” Global demand has nearly doubled over the last 20 years. As a result dozens of new manufacturing plants have recently opened in the US. More are under construction or being planned. If all of them were to become fully operational, they could collectively generate an additional 55 million tons of greenhouse gases by 2025. That’s the equivalent of adding 27 500-megawatt power plants to the mix.

So what can we as designers do about it? And can we do it fast enough to matter?

THE SORCERER’S APPRENTICE

Climate change is tracked by parts per million (ppm) of atmospheric carbon. 350 ppm is considered safe and 450 ppm is the point of no return. Currently, we are hovering in the 400-teens ppm and climbing fast.

If there were the equivalent of a “350” for plastic, we blew past it decades ago.

Climate weirding turns out to be the easier problem to fix: Reduce GHG emissions, transition to clean energy sources, leverage efficiency so less energy is needed, and sequester as much carbon as possible, preferably in the soil where it can help build micro-biodiversity. It is a tall order and the clock is ticking, but the marching orders are fairly straightforward.

Plastic is more of a Sorcerer’s Apprentice problem: Not only is more plastic being produced each and every year, but with a global population closing in on 8 billion, more of us are using more plastic each and every year, too. That means that although 60% of PET bottles are recycled in Europe (about twice as many as in the US), the absolute number of bottles not being recycled continues to grow.

At 60%, 600,000 bottles are recycled for every million bottles. That leaves 400,000 bottles that aren’t.

About a million bottles per minute are produced.

Let’s repeat that.

About a million bottles per minute are produced, so we are losing ground. Fast.

And that’s just bottles. All told, the recycling rate is less than 10% globally. Which means that 90% of all the plastic currently produced is still with us in one form or another — along with all the legacy plastic that predates recycling:

-

It is in the water, swirling around in vast marine “garbage patches,” breaking down into microplastics. (This isn’t only an ocean problem, but is also happening in lakes, ponds, rivers, streams, creeks, and puddles.)

-

It is in the land, slowly breaking down in landfills, a process that can take centuries, leaching chemicals all the while. It is in the trash that is almost everywhere you look. (The land plastic problem doesn’t get as many headlines, but dwarfs the marine plastic problem.)

-

It is in the air, released as toxic gases when plastic trash is burned.

-

It is in the air in the form of microplastic particles that travel the globe on wind currents and fall to earth in rainstorms. Yes, we now have plastic rain.

So much plastic has piled up and insidiously worked its way into the food chain that researchers are starting to refer to the “plastisphere,” a new ecosystem of microbes, plants, and animals — including us — connected by plastic and evolving accordingly.

We eat microplastics in our food. We inhale microplastic fibers from our clothing. We drink microplastics along with the water, soda, and milk that fill all those technically recyclable PET bottles.

Factoids meant to shock and impress, shock and impress:

-

By 2050, there could be more plastic in the ocean than fish

-

A young whale dies of starvation with a stomach stuffed with nearly 90 lbs of plastic

-

Over a typical 79-year lifespan, a human can ingest 20 kg (about 44 lbs) of plastic

So either we figure out a better way to deal with plastic.

Or we become plastic.

DREAM TO NIGHTMARE

At COLLINS, we often talk about “the next dragon.” This is a reference to the story of Beowulf, whose efforts to protect a town from the predations of a fierce and voracious dragon kept coming up short. Kill the dragon and the dragon’s mom — a real piece of work — goes on the attack. There is always a “next dragon.” As designers, it is our job to help our clients figure out what their “next dragons” are, then figure out how to deal with them.

The plastic dragon, though, is a dragon apart: an existential threat to everything that walks, crawls, slithers, wriggles, gallops, floats, flies, swims, and grows on Earth. It is a crisis in the here and now that threatens to blight generations far into the future. The plastic dragon came with its mother — and all of her friends — to do battle.

It is literally a shape-shifter. You think you’ve gotten rid of one plastic dragon and it turns into bazillion microplastic dragonettes. You think you’ve got a handle on the dragonettes and they dissolve into countless, noxious chemical dragon-bits.

••••••••••••••••••••••

Yet when plastic — invented in the 1850s — found its first commercial use as cellophane to wrap a bright yellow Whitman’s Sampler candy box in 1912, it seemed like a miracle: a nearly weightless, transparent, flexible wrapping that could preserve the freshness not only of candy, but also of bread, vegetables, and meat. In the years before electric refrigerators and freezers, people used ice-boxes to keep food fresh. Plastic saved a lot of food from going to waste. It also didn’t break and shatter like glass. It was light and cheap and amazing.

It still seemed like a miracle a half-century later in 1963 when McDonald’s introduced the squared-off, plastic milk jug, which made it possible to more fit more jugs in a fridge. The global population was 2.8 billion (roughly 1/3 of what it is today) and atmospheric carbon clocked in at a climate-friendly 318 ppm.

A dozen years later Coca-Cola introduced its first plastic bottle. In 1975 the global population had increased to 4 billion. CO2 levels were still well within the safe zone at 330 ppm.

Plastic, like climate change, just didn’t seem like a problem. Fossil fuels opened up new horizons. (Highways that crisscrossed the nation!). Cars were cool. (Corvettes and Mustangs and Chevy Camaro sports coupes!). Jet-setting was the future. (Three hours from Paris to New York on the Concorde!)

Fossil fuels made modern life modern.

••••••••••••••

Yet there were those who saw the fraught road ahead. In fact, Exxon Mobil invested in pioneering research as far back as the 1970s that painted a bleak future for its business. Exxon understood the link between fossil fuel emissions and climate change, but rather than share that literally Earth-changing news with the public and begin planning for a post-fossil fuel future, the company invested in front groups to question the science and sow doubt among the public. It is a tactic that they and others are accused of continuing to use to this day, prompting a new round of Congressional hearings.)

Forty years of denialism later and Hurricane Ida — ginned up by the hot waters of the Gulf of Mexico (several degrees warmer than average due to climate change) — slams into Port Fourchon, an oil and gas hub on the Louisiana coast. The port services 90% of the Gulf’s deepwater oil production and handles as much as 15% of the world’s oil supply. Nearly all of it was either shut down in advance of Ida, rerouted, or damaged by the storm.

A direct hit, served up with a hot slice of “Don’t Mess with Mother Nature” karma.

Oil and gas production are bad bets in a climate-changing world. The assets are vulnerable. Pipelines and wellheads can freeze from a dip in the Polar Vortex or be damaged from a direct hit by a tropical cyclone. Even in perfect weather, a stray anchor can cut a gash in an underwater pipeline and foul a coastline. And a cyber-attack can happen at any time.

It is astonishing how much time has been squandered. In the late 1970s, atmospheric CO2 was about 335 ppm, still well within the safe zone. But decades of well-crafted disinformation campaigns by fossil fuel companies — that included plenty of money for politicians to turn a blind eye — and we find ourselves at the edge of disaster.

We are the generation they didn’t care about. Our present is the future they sacrificed for a fat bottom line and a high stock price.

Now, faced with exponentially more daunting challenges, we have to do better. We have to give a damn.

We can follow Rachel Carson’s lead.

••••••••••••••••

In 1944, Rachel Carson, an aquatic biologist with the US Fish & Wildlife Service and author (Under the Sea-Wind), proposed an article to Reader’s Digest magazine about the environmental dangers of DDT, a popular pesticide at the time. It was rejected for being too “unpleasant” a topic. (DDT was eventually banned in the US nearly three decades later in 1972 in large part due to Carson’s research.)

It would take almost 20 years — which saw the publication of a second book (The Sea Around Us), a Guggenheim fellowship, a slew of awards, and an ongoing battle with breast cancer — before Carson would take on the “unpleasant” topic and more in Silent Spring, her most famous book.

Carson was writing about petrochemical pesticides, not plastics. But along with oil, gas, and coal, it is all of a fossil fuel piece. The lion’s share of a barrel of oil isn’t used for fuels, but refined for petrochemicals, including those used to make plastic. Plastic can also be made from natural gas, including fracked gas, whose extraction is a major source of methane, a greenhouse gas 25 times as potent as CO2.

While chemical companies were narrowly focused on profitable applications such as killing bugs that threatened agricultural crops, Carson took a systems approach. She wanted to know about collateral damage: What else was killed off? What ate the dead bugs? Could poisons circulate through the food chain? And what did the loss of species, even pesky bugs, mean in the greater scheme of things?

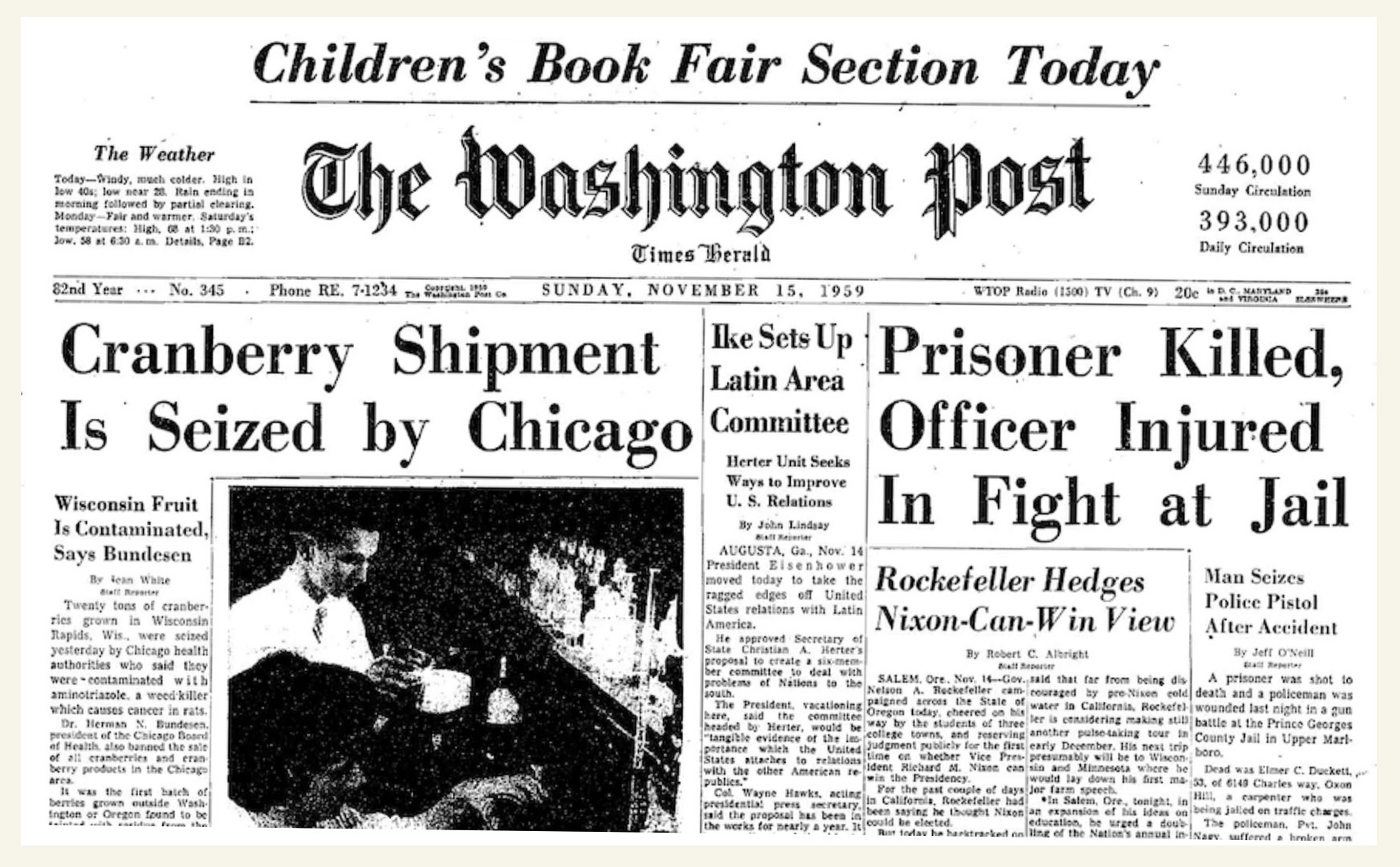

Silent Spring, which was first serialized in The New Yorker in the summer of 1962 (and went on to sell two million copies), resonated with a public that had been rocked three years earlier by the “Cranberry Scare of 1959.” When scientists found a link between cranberries sprayed with aminotriazole and throat cancer in rats, the USDA pulled cranberries off grocery store shelves right before Christmas. Chemical companies howled over the financial pain. And a presidential candidate, John F. Kennedy, took note.

A month before the first installment of Silent Spring appeared in The New Yorker, JFK’s Science Advisory Committee published a study raising troubling questions about pesticide safety. By August, the President referenced Carson’s work as motivation to dig even deeper into the topic. In October, Silent Spring became a Book of the Month Club pick.

Carson’s critics were enraged and did their level best to discredit her as a scientist, often citing her gender as a disqualifying handicap, a kind of “pre-existing condition” from which there was no recovery. Despite the vicious onslaught — she was accused of being hysterical, radical, a witch, and a communist sympathizer during the height of the Cold War — Carson testified before two Senate committees while she was battling the cancer that would kill her in 1964.

Rachel Carson is often credited with kickstarting the environmental movement, and she certainly was a galvanizing force. But there were many scientists and conservationists who could also see the catastrophe looming on the horizon. She happened to be the one who could write, the one brave enough to give voice to those who would be silenced.

That’s our bar.

HOW TO SLAY A PLASTIC DRAGON

We are long past the point of “plausible deniability.” Nor is there any time left for corporate greenwashing or greenwishing. Good intentions won’t cut it. Companies that talk about switching to 100% recoverable or recyclable materials within the next three or four years need to up the stakes and show exactly how their products will be recovered or recycled. Then track and report progress. Anything less is not enough.

Taming the plastic beast is a three-front battle. And designers are essential for the success of all three.

Materials Design

Plastic is a fabulous material with a lot to offer and a couple of deal-killer flaws. It’s lightweight, flexible, moldable, durable, printable, and water-proof. It can be transparent or take on color. And it’s cheap. We need alternatives that are all that and better: materials that don’t leave behind centuries-and-longer legacies of garbage, microplastics, and poisons. There is no one-size-fits-all answer, but in the last decade several contenders have emerged:

-

Seaweed materials are a circular economy darling. This ubiquitous marine staple grows prodigiously and sequesters vast amounts of atmospheric carbon: No fertilizers or pesticides required. It grows along coastlines all over the world, which means it is possible to set up distributed production: No giant supertankers or pipelines required. Best of all seaweed materials are compostable, breaking down into compounds that can actually benefit the environment: No pricey cleanups required. Several companies are developing seaweed-based plastics including start-ups Sway and Notpla, and also DS Smith, a UK-based, multinational packaging powerhouse. The company is experimenting both with seaweed-based cardboard (its signature product), which would reduce the need to source trees for wood pulp, and also with a seaweed-based, water-proof barrier coating for inside cartons — a holy grail in recyclable package design. Meanwhile, Mohawk, known for its “Renewal” line of environmentally-friendly papers made from recycled cotton, hemp, and straw has developed a replacement for plastic exhibits and retail displays called “Xanita Board.” Xanita, which is made from post-consumer recycled cellulose (e.g., Kraft cardboard boxes), is 100% repulpable and recyclable, making it a circular material. It is also easily cut to specifications and ink jet-printable. It isn’t simply a replacement for plastic, but a better answer altogether.

-

Mushroom materials also check a lot of environmental boxes. The pioneer in the field, Ecovative Design based in upstate New York, started with a “think different” idea in 2007 to grow an alternative to polystyrene packing materials based on mushroom mycelia. Mycelia (mushroom rootlets) can be grown in forms to any shape desired, feasting on wood waste in an emissions-free, zero-energy production process that requires neither heat nor cooling. Once the packaging has performed its function, it is home compostable, the gold standard of dust-to-dust circularity. Over the years, Ecovative has branched out into mushroom-based skincare, apparel, and food products.

-

Biomass materials are poised to scale up with technologies developed by Origin Materials, a company that went public on the NASDAQ earlier this year with a billion-dollar-plus valuation. Origin uses sustainably sourced wood waste and other biomass to create cost-competitive alternatives to petroleum-based materials, including polyester, asphalt, and, of course, plastic. Consumer brands including PepsiCo, Danone, and Nestle are interested in Origin’s plant-based PET (polyethylene terephthalate) to use for bottles. Although better than fossil fuel-based PET, its environmental-friendliness hinges on whether this recyclable product is in fact recycled.

-

NextWave, a consortium of multinational technology and consumer brands isn’t inventing a new material, but instead developing a supply chain and establishing a new commodity: “ocean-bound plastic.” This is plastic trash — aka “mismanaged waste” — found within 50 miles of a coastal area. Each year eight million metric tons of plastic is added to the Earth’s oceans and waterways (the current tally is 86 million metric tons). NextWave’s goal is to divert plastic before it becomes part of a marine garbage patch. The consortium works with local pickers who bring their hauls to local processors where the plastic is ground up, washed, and pelletized. The pellets are sold to NextWave members who use them to create all sorts of products. The latest is Herman Miller’s iconic Aeron Chair. The company is on track to use at least 50% recycled content in its products by 2030.

-

New research from the Woods Hole Oceanographic Institution (where Rachel Carson occasionally worked) could help materials scientists design more environmentally compatible plastics. Scientists took several, standard, single-use store bags, tossed them into sunlit surface waters, then studied what happened to them. The good news is that the bags degraded significantly faster than anyone thought they would, in a matter of few months, rather than years, decades, or longer. The bad news is that the bags dissolved into thousands of water-soluble “formulas” that may — or may not — be harmful.” By simply modifying the ingredients in their recipes, the plastic industry can make their products more susceptible to breakdown once the product reaches its useful lifespan,” noted study co-author Christopher Reddy.

Packaging Design

A staggering 40% of plastic is used for packaging, and much of it is single-use. Retail store bags are just the beginning. Every tasty tub of cottage cheese and carton of sweet ice cream, every bottle of refreshing water, soda, and milk, and every bag of crunchy chips is at least in part, if not entirely, made of plastic. How do we use less?

-

Under the aegis of the Ellen MacArthur Foundation, a series of “Plastic Pacts” are being hammered out around the world, each bringing together businesses, governments, NGOs, research institutions, recyclers, and other stakeholders. The US Plastics Pact, currently being finalized, is spearheaded by The Recycling Partnership and World Wildlife Fund. The overarching goal is to make 100% of all plastic packaging recyclable or recoverable by 2025, which is only a few years away. The big challenge for 2021 — a year with only a few months left — is to come up with lists of “problematic” and “unnecessary” plastics that can be eliminated. Polystyrene packing peanuts, you are so over.

-

Packaging consultancies such as Guacamole Airplane as well as large manufacturers such as DS Smith work closely with brands to design packaging that uses less material. DS Smith has also developed a free pdf guide on *Circular Design Metrics*. Like all good ideas, this one generates multiple benefits, including the potential for significantly lower production and shipping costs. According to a recent survey, sustainable packaging is a major driver of e-commerce loyalty. Customers care, so how brands stack up on sustainable packaging is now an important part of the brand story. Perhaps a reflection of the imagination-loosening product within, but wine and spirits companies have some of the best stories to tell, with cardboard bottles, flat bottles, returnable bottles, and more.

-

Take Back/Reuse is another strategy to create eddies of circularity within the bigger plastics pond. Loop, which was launched at the World Economic Forum in 2019, works with several major consumer brands, including Procter & Gamble, Mondelez, and Unilever, to provide customers with a reusable packaging alternative for their products. Clubzero is the rebranding/rebirth of CupClub, a company that has rethought coffee cups and to-go containers as a service. Customers at participating coffee shops and cafes can put their cups and containers into a Clubzero bin instead of a garbage can. They are then picked, washed, and returned for reuse. Clubzero is currently being piloted in the UK where proposed bans against single-use plastic support the business model. In the US, a review app called Jybe helps restaurant-goers identify eateries that use eco-friendly packaging and utensils. Jybe also works with restaurants to identify greener alternatives that are often cost-competitive and sometimes cheaper.

-

There are several ways to reduce the need for plastic packaging, but only one reduces the need to zero: dematerialization by digitization. Spotify made petroleum-based vinyl records and plastic CDs irrelevant. No more shrink wrap. No more plastic CD “jewel cases.” And no more bulky, mostly plastic record players and cassette decks. In talking about plastic, we often overlook what we no longer use.

Systems Design

Less than 10% of all the plastic ever made has been recycled because a patchwork of recycling systems around the world were designed to fail. There is still a lot of money to be made in fossil fuel-based plastic. In the US, billions of dollars are being invested in new plastics plants along the petrochemical-saturated Gulf Coast and in Pennsylvania, near fracking operations. Virgin plastic “nurdles” made from cheap gas and oil are cheaper than recycled plastic. In a commodity market, cheaper is hard to beat, even if it comes at high environmental and public health cost. It isn’t only that recycling systems need to be designed to succeed, but also that the externalized costs of pollution need to be accounted for. Recycling is as much about policy and politics as it is logistics.

- In June 2021, more than 100 global brands and 50 organizations (including Barcelona-based design school Elisava) signed an Ellen MacArthur Foundation-crafted pledge to support Extended Producer Responsibility (EPR) schemes. EPR means that manufacturers that use plastic packaging, including PET bottles, will take ownership of the problem and fund recycling programs.

…While, in theory, there could be many ways to provide this funding, in practice, the only proven and likely pathway to ensure dedicated, ongoing, and sufficient funding at scale is through mandatory, fee-based EPR schemes, in which all industry players introducing packaging to the market provide funding dedicated to collecting and processing their packaging after its use. The alternatives — relying on funding from public budgets or from voluntary contributions — are unlikely to scale to the extent required and fall short of being dedicated, ongoing, and sufficient…

-

What this will look like in practice remains to be seen. But a second “Clean Creatives” pledge authored by Jamie Henn, founder of Fossil Free Media, ought to make it harder to “pull an Exxon” and skirt doing the real work. (Henn was also one of several co-founders‚ including writer/activist Bill McKibben, of 350.org.) “Creativity has consequences: If you are making a flashy ad that’s greenwashing a fossil fuel company, it doesn’t matter how creative it is, or how pretty it is, it’s doing real damage…” So far, more than 100 PR and advertising agencies have signed on.

-

Getting recycling right is critical, but it won’t be enough to make a dent in the mountains of plastic that have accumulated over the last century — in recent years, an average of 300 million tons annually. In 2016, scientists discovered a plastic-loving bacterium in the muck near a plastics plant. In the five years since, dozens of bacteria and also fungi with a taste for plastic have been identified. It makes sense. Microbes have a long history of helping to mitigate oil spills. We see waste. They see food. Now comes long, hard work of figuring out how the microbes do it, isolating plastic-dissolving enzymes, and scaling it for commercial use. Perhaps some of the EPR funds could be used to support research.

LEGACIES

Only within the moment of time represented by the present century has one species — man — acquired significant power to alter the nature of the world.”

― Rachel Carson, Silent Spring

That was written in the last century. More than a fifth of the way through the current century, time is running out to use that power to make sure future generations have a cleaner, better world than the one we inherited. We are paying the price of a generation that knew better but didn’t do better.

Let’s make sure that isn’t our legacy as well.

As designers, the urgency of our mission is clear. A cleaner, better future demands profound systems change, one where circular materials and minimalist packaging are the norm and recycling schemes are optimized for success.

We will slay the plastic dragon because we must.

Artwork by Dev Valladares, Designer at COLLINS.